SPANK INDUSTRIES rims are precision handcrafted in our own factory, FRATELLI INDUSTRIES. Each rim undergoes 12 quality control checks before it reaches you. In order to optimize the robust, yet light-weight to performance ratio you expect, SPANK INDUSTRIES has developed a number of patented technologies which begin with the design principles of our products, are implemented meticulously during our material processing and manufacturing methods, and ultimately tested in the field by our professional factory athletes before we make them available to you.

Alloys Only

SAFE, AFFORDABLE AND RESPONSIBLE ALTERNATIVE TO CARBON FIBER.

Utilizing the endless lifecycle of aluminum, our proprietary alloy blends offer superior mechanical properties resulting in stronger rims and reduced weight through optimized design.

From rim extrusion, through to final product, each rim is passed through twelve quality control tests.

REFINING & STRENGTHENING

MICRO GRAIN REFINEMENT PROCESSED ALLOYS.

Processes such as extrusion, forging and tube drawing increase the strength of alloy materials by reducing the grain size. You'd be hard-pressed to find other alloy rims that are subjected to the number of drawing steps or level of refinement as those offered by SPANK IND.

OOHBAH

INVERTED TUBE WELL DESIGN FOR GREATER CROSS SECTIONAL STRENGTH. WIDER, LIGHTER RIMS.

The unique OohBah™ profile allows us to manufacture thinner walled, wider profiled, lighter rims without sacrificing strength or rigidity. Wider rims mean stiffer wheels and more tire spread, leading to greater traction and improved comfort, and tire performance. The “wave” shape of the OohBah™ inner tube adds strength and support to the vertical rim flange walls and prevent buckling. Normal straight or curved tube wells must be much thicker, and by default heavier, to offer the same support. It is one of the main reasons so many describe our rims as ‘bombproof’, while it also promotes easier tubeless inflation.

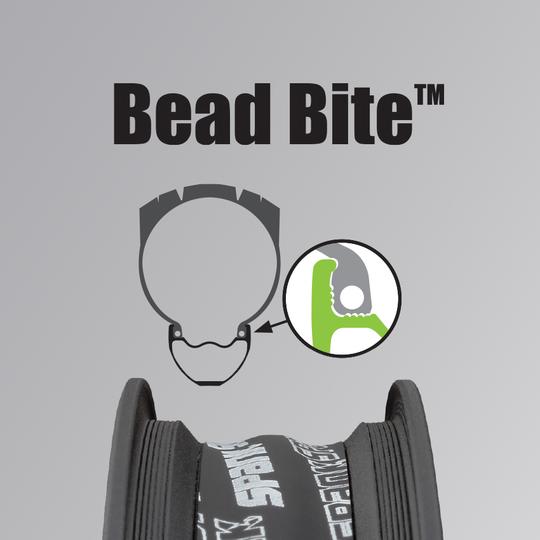

BEAD BITE

ENHANCED ANTI-BURP AND TIRE RETENTION TUBELESS PERFORMANCE.

SPANK INDUSTRIES BEADBITE is a unique design feature that optimizes set up for tubeless and reduces burps or pinch flats.

Tire beads are locked in place between vertical and horizontal ridges. 12 sets of ridges on the vertical and horizontal walls create tiny air seals, improving retention. Vibrocore reduces negative vibration and increases lateral stiffness & torsional strength.

VIBROCORE

STRONG WHEELS WITH ENHANCED COMFORT

Vibrocore is a pressurized foam core that reduces the transmission of negative vibration and helps to balance Radial Compliance and Torsional Strength, delivering rigid, strong wheels with enhanced comfort and traction. Performance benefits include:

Wide and low profile adds significant radial compliancy.

New profile increases lateral stiffness and torsional strength.

Vibrocore™ inner well maximizes torsional strength in a light weight, vibration damping core.