SPANK INDUSTRIES

BUYER'S GUIDE PEDALS

The original, multi award-winning alloy flats with industrial bushings & bearings & a bombproof legacy.

SPANK INDUSTRIES INHOUSE

DESIGN & MANUFACTURE

Forging alloy in a mould, piece by piece, for a stronger yet lighter alloy pedal, needs more time, and ultimately costs more. But this is just the beginning of what we invest into bringing a superior pedal to the market.

We equipped ourselves with a latest-technology in-house pedal manufacturing centre. Employing 5 Axis CNC machines, PCD Diamond cutting tools from the leading automotive supplier in Germany, and Swiss-made fixtures, we have spared no expense to develop and improve on our pedal platform.

Because we specifically designed our own new complete manufacturing lines to satisfy our need for a superior pedal, we can now achieve tolerances and consistency normally reserved for the aerospace industry.

Since pedals are one of the primary contact points between rider and bike, SPANK Industries has applied special care to the fit and function of our pedals to find the perfect fit for every rider. Few people consider proper fit when it came to flats. However, grip, safety, and overall comfort and confidence are greatly increased with the right pedal model selection for each person’s specific foot size, and riding style.

Before you choose a pedal model from SPANK's range, take a moment to understand the design engineering of our pedals.

5 AXIS CNC

Whether forged Spike and Oozy Trail Pedals, extruded and sized Spoon pedals, or economic die cast Spoon DC pedals, SPANK uses only industry leading equipment. SPANK invested in a precision, pedal specific 5 axis CNC line, fixtures custom produced in Switzerland, and diamond tipped cutting bits from Germany’s leading automotive supplier.

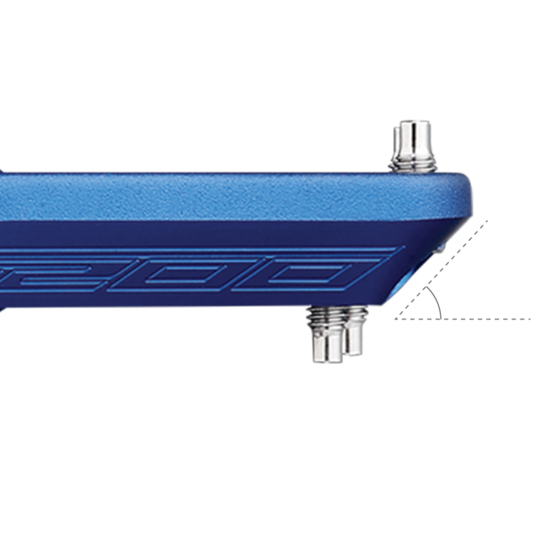

CHAMFERED LEADING EDGES

SPANK’s iconic chamfered leading edges on all pedal models were a game changer in pedal design. Forward edges are angled to deflect impacts and glance off obstacles, reducing pedal strike accidents and crashes, and increase pedal clearance in high speed turns.

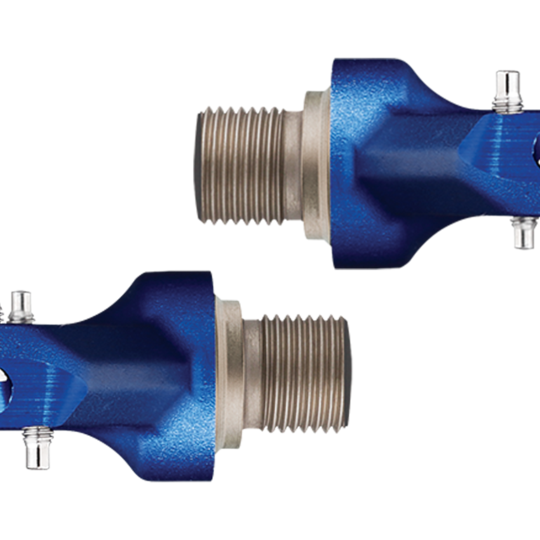

LOW Q-FACTOR

Q-Factor (the distance between your feet while riding), should be kept as low as possible for efficiency, maneuverability and clearance. Where most pedals unnecessarily add to the Q-Factor with a wrench interface between the pedal and crank, SPANK pedals mount from the backside of the crank, placing them as close as possible to the cranks.

LOW CENTER OF GRAVITY

While pedal thinness is an important factor for pedaling clearance, SPANK pedals also prioritize keeping the rider’s foot as close as possible to the pedal axle, where other pedals are often thickest in this zone. This decreases the need to maintain balance over the pedal axle, improving grip and pedaling efficiency, and reducing dangerous pedal flip.

FORGED CHROMOLY AXLES

From Spoon 90’s for smaller riders, to Spike Flats for heavy hitters, SPANK designs and produces custom pedal axles for all our pedals, from cold forged Chromoly steel, providing the ultimate in strength and safety, and lowest weight.

CRANK BOOT COMPATIBILITY

Q-Factor (the distance between your feet while riding), should be kept as low as possible for efficiency, maneuverability and clearance. Where most pedals unnecessarily add to the Q-Factor with a wrench interface between the pedal and crank, SPANK pedals mount from the backside of the crank, placing them as close as possible to the cranks.

IGUS SMART PLASTIC BUSHINGS

SPANK pedals were the first to utilize custom Smart Plastic pedal bushings from the top producer, IGUS. Today, long lasting, self-lubricating IGUS bushings are more common in high end frames and pedals, due to their superiority to traditional DU bushings. IGUS bushings feature in all SPANK pedals from Spoon DC to Oozy Trail.

SEALS AND INDUSTRIAL BEARINGS

SPANK uses only pedal specific, custom, Industrial Grade bearings in all our pedals. Bearings are protected from moisture and contamination by axle seals on both inboard and outboard ends. Ingenious Friction Seals also help to reduce pedal free-spin, while ensuring the longevity of bearings and pedal function.

TRACTION PINS

Spike, Oozy, and Spoon Pedals are pre-assembled with steel, full length 9mm, rear-load traction pins at the outer edges, which maximize grip, and allow exposed pins to be replaced if deformed from impacts. The tips of each pin are machined, to prevent thread damage.

Spoon DC Pedals use shorter 7mm steel traction pins, making them safer for less experienced riders, and allowing more freedom of foot movement for disciplines such as pumptrack and dirtjump.

NEW

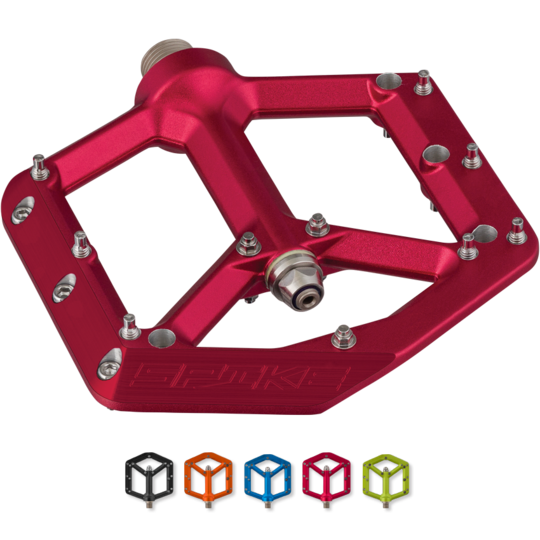

OOZY REBOOT

Full anodized new colour range and the new crank boot compatible Reboot axle.

FAVORED CHOICE FOR TRAIL AND ENDURO

SPANK OOZY REBOOT

OOZY pedals are recommended for those who prefer a good balance between light weight and ultimate strength, but don’t impact their pedals quite as often or hard.

Spike and Oozy Trail Pedals have a large asymmetric polygonal platform, anatomically designed to offer maximum support and traction with the slimmest pedal body possible, at just 12mm thin.

They feature 100 x 100mm of actual contact surface on each side, which is perfect for most adults. These pedals have been designed for high level, aggressive riding, whether DH/FR, or Trail/Enduro, maximizing pedal clearance both when pedaling and cornering.

NEW

SPIKE REBOOT

Full anodized finish, and fitted with the new crank boot compatible SPANK Reboot axle.

TOP CHOICE FOR FREERIDE & DH FLATS

SPANK SPIKE REBOOT

SPIKE pedals are recommended for the heaviest hitting riders, who often experience pedal impacts.

NEW

SPANK SPOON

New range of 8 new full anodized colours, perfectly colour-matched to the new SPOON stem & handlebar range.

AVAILABLE IN THREE SIZES

SPANK SPOON PEDALS

Spoon 110 Pedals are the largest in the Spank pedal line, with a wide 110x105mm platform. This makes the Spoon 110 perfect for large riders with shoe sizes US 11 and above, or for riders who often wear bulky boots (example snow riders). The 16-12mm concave profile still feels remarkably thin compared to traditional flat pedals, and provides an exceptionally locked in feel.

Spoon 100 Pedals have a medium sized 100x105mm platform, designed for average sized riders, with shoes from US size 7-10. They have a 16-12mm concave profile which delivers a thin ride feel and exceptional levels of traction.

Spoon 90 Pedals are the smallest in the Spank line, and an upgrade for most young or smaller riders, with shoe sizes US 6 and under. Despite the narrow 90mm width, Spoon 90’s offer exceptional support, and traction, due to a 105mm length. The Spoon 90’s are also often favored for those riding in exceptionally tight trail areas, where other pedals tend to get hung up on obstacles to the sides of the trail.

ALLOY VS COMPOSITE

SPOON DC

At SPANK, we choose alloy over composites, always! Alloy is stronger, recyclable and more environmentally sustainable than plastic composite production.

At the price range of a composite pedal, you get a SPANK INDUSTRIES alloy technology pedal with robust axle, bearings & bushings, and the option to upgrade from 7mm to 10mm pins.

ALLOY PEDALS AT THE PRICE OF COMPOSITE!

SPANK SPOON DC PEDALS

These pedals share the same versatile, medium size, 100x105mm platform as the Spoon 100, however are designed to offer a slightly less locked in feel, improved ease of maneuverability when riding, and less danger from shin strikes due to shorter traction pins. This makes them the ideal solution for disciplines like dirt jump and pumptrack, and for less advanced riders. Traction can be upgraded with a full length pin kit when and if desired.